In the world of industry, where artistry meets innovation, lies the realm of paper factories. These unassuming structures house intricate machinery that transforms raw materials into the versatile sheets of paper we encounter daily. Join us on a journey into the heart of these factories, where the art and science of paper production come together in a mesmerizing dance.

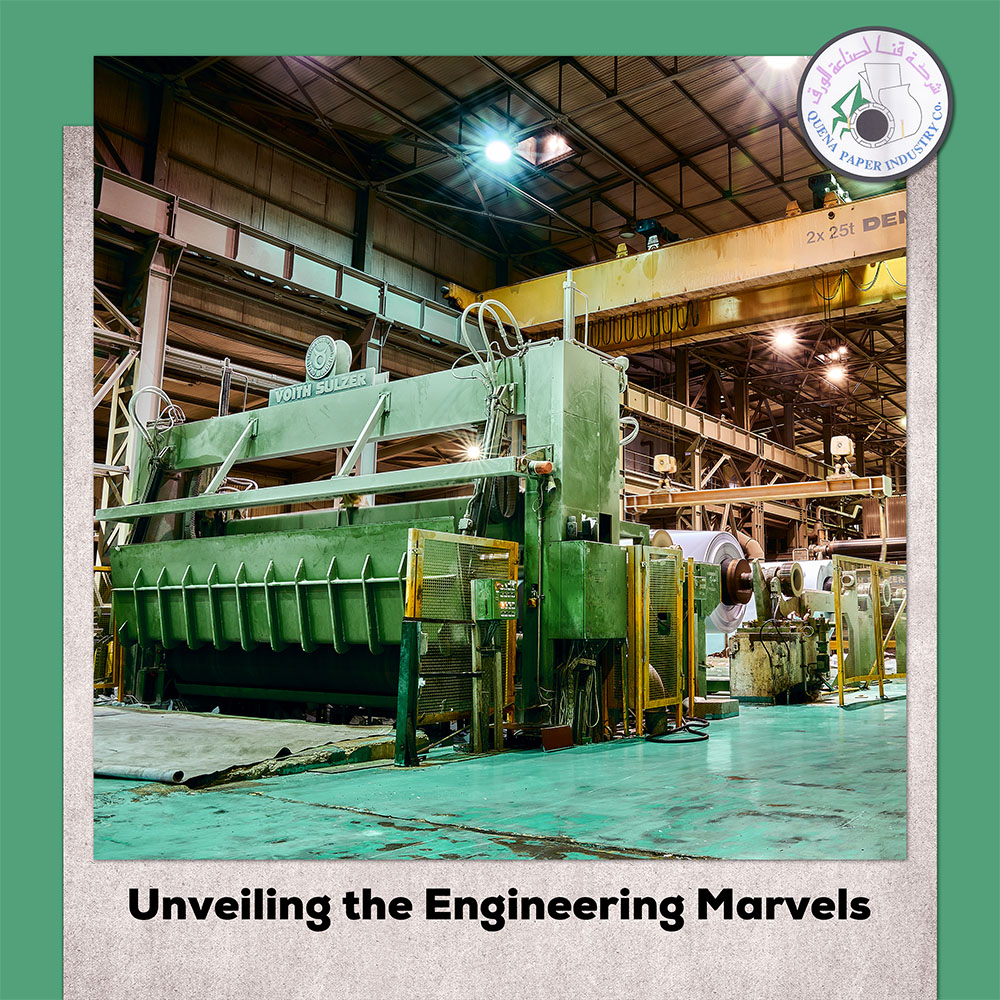

Unveiling the Engineering Marvels

At the core of every paper factory are engineering marvels that have evolved over centuries. The raw material, often wood pulp, goes through a series of meticulously designed stages, each with its own purpose. From the initial pulp preparation, where fibers are separated and refined, to the subsequent addition of chemicals for desired properties, the process unfolds like a symphony.

The process begins with the sourcing of raw materials, most commonly wood pulp. The pulp preparation stage involves transforming these raw fibers into a workable substance that can be molded into paper. In this stage, the raw material undergoes cleaning, refining, and mixing with chemicals. The result is a uniform and consistent pulp mixture that serves as the foundation for the paper-making process.

From Pulp to Perfection: Stages of Production

Pulp Preparation: Laying the Foundation

The journey begins with the pulping process, where wood fibers are extracted and transformed into a malleable substance. This initial step sets the stage for what is to come, determining the quality and characteristics of the final product. The wood is debarked, chipped into small pieces, and then subjected to heat and chemicals in a pulping digester. This breaks down the wood fibers, separating them from other components like lignin and hemicellulose. The result is a fibrous pulp that forms the basis of paper.

Formation and Pressing: Giving Shape to Dreams

Once the pulp is ready, it embarks on a path of formation and pressing. This is where the future paper takes shape. Layers of fibers intertwine to create a web, and water is extracted, leaving behind a compact structure that is the basis for the next phase. The pulp mixture is spread onto a wire mesh conveyor, allowing water to drain away. This forms a wet mat of fibers that moves through press rollers. The pressing phase removes more water, consolidating the fibers and forming a preliminary sheet of paper.

Drying and Calendaring: Crafting the Texture

The formed paper enters the drying and calendaring stage. Heat and pressure are applied to remove the remaining moisture, resulting in a surface texture that ranges from smooth to textured, depending on the intended use. The paper passes through a series of heated rollers that evaporate the water, leaving the fibers tightly bonded. The calendaring process involves additional rollers that smooth and polish the paper, giving it the desired finish.

Merging Precision and Innovation: Role of Automation, Robotics, and AI

In the age of technology, paper factories have embraced automation, robotics, and AI to streamline operations and elevate quality.

Automation: Precision Redefined

Automation has redefined precision in paper manufacturing. Automated systems monitor parameters such as moisture levels and fiber distribution, ensuring consistency in every sheet produced. This not only boosts efficiency but also reduces the margin of error. Sensors placed at various points in the process continuously gather data, feeding it to a central control system that adjusts conditions in real-time. This level of automation ensures that each sheet of paper meets the desired specifications.

Robotics: A Helping Hand

Robotic arms delicately handle delicate tasks, such as loading and unloading materials, as well as maintenance. Their agility and accuracy have proven indispensable in maintaining a smooth workflow. For instance, in the loading and unloading process, robotic arms carefully pick up stacks of paper and place them on pallets, minimizing the risk of damage or inconsistencies.

AI: The Mind Behind the Machines

Artificial Intelligence has become the mind behind the machines. Advanced algorithms analyze data in real-time, making instant adjustments to optimize processes. This technology also aids predictive maintenance, prolonging the lifespan of equipment. AI algorithms process data from sensors, historical records, and performance patterns to predict when maintenance is needed. By addressing issues before they escalate, downtime is minimized, and the overall efficiency of the factory is maximized.

Challenges and Triumphs: Navigating Complexity

While these technological advancements have revolutionized paper production, they haven’t come without their fair share of challenges.

Maintaining Complexity

The intricate machinery requires skilled technicians to ensure its proper function. Maintenance and repairs demand a deep understanding of both mechanical and digital components. Technicians must be adept at troubleshooting issues in the physical equipment as well as diagnosing problems within the digital control systems. Regular training and ongoing education are crucial to keep up with the evolving technology.

Upgrading for the Future

The ever-evolving landscape of technology necessitates regular upgrades to stay competitive. Manufacturers walk a tightrope between tradition and innovation, seeking to incorporate modern solutions without disrupting time-tested processes. Upgrading machinery involves not only integrating new hardware and software but also ensuring compatibility with the existing infrastructure. This challenge requires careful planning and execution to minimize downtime and maintain product quality during the transition.

The Fusion of Creativity and Technology

In the captivating world of paper factories, the synergy between creativity and technology is evident. The machinery, like a conductor’s baton, orchestrates a blend of raw materials, engineering precision, and innovative automation to craft the everyday wonders we often take for granted.

As you reflect on the paper that fills your life, remember that behind each sheet lies a fascinating journey of art and science, guided by the hands of engineers, supported by the strength of robotics, and directed by the intelligence of AI. It’s a testament to human ingenuity that continues to unfold, one sheet at a time.

The Ongoing Evolution

The art and science of paper factory machinery continue to evolve, driven by a quest for greater efficiency, sustainability, and quality. As new materials and technologies emerge, the production processes will likely become even more sophisticated. The blending of creativity and technology remains at the heart of this evolution, ensuring that the paper we use in our daily lives is not only functional but also a work of craftsmanship. So the next time you hold a sheet of paper, take a moment to appreciate the intricate journey it undertook from raw pulp to finely crafted wonder.